Medical and Operating Rooms, Industrial and Food Process Dehumidifiers, Corrosion Prevention Dehumidifiers, and Low and Ultralow Depoint Dehumidifiers

Desiccant dehumidifiers provide a highly effective solution for removing moisture from the air in low temperature and low humidity environments. Desiccant dehumidifiers use a desiccant material that attracts and absorbs water vapor, removing moisture from the air.

Desiccant dehumidification systems are commonly used for applications below 45% RH down to 1% RH. They are well suited for applications where there is a need to independently control the temperature of the space and the moisture level or humidity of the space.

Ready to purchase your very own desiccant dehumidifier? Request a quote to get started today!

Mojave Desiccant Dehumidifiers

Mojave’s ArctiDry is an innovative, next-generation liquid desiccant air conditioner and dehumidifier that can reach dewpoints as low as 35°F without the need for reheat. It offers the option to operate in heat pump mode as low as 10°F ambient, with supplemental heating options, including gas, electric, and hot water. AcrtiDry is easy to operate and maintain, and is installed like conventional packaged HVAC equipment.

Product Specifications

Airflow Capacity

- A Cabinet: 1,000–3,000 CFM

- B Cabinet: 3,000–6,000 CFM

Cooling Capacity

- A Cabinet: Up to 25 tons

- B Cabinet: 25–60 tons

Moisture Removal Rate

- A Cabinet: Up to 130 lb/hr

- B Cabinet: Up to 380 lb/hr

Supply Air Conditions

- Dry Bulb: 55–75°F

- Dew Point: 35–55°F (30–64 gr/lb)

Efficiency

- ISMRE up to 11 lbs/kWh

- Exceeds DOE standard of 3.8 lbs/kWh

Heating Options

- Reversible heat pump

- Gas, electric, or hot water supplemental heating

Refrigerant

- R-454B (GWP of 466)

Construction

- 2″ double-wall with R-13 insulation

- Weights: A Cabinet ~3,500 lb; B Cabinet ~6,500 lb

Controls & Integration

- Factory-packaged controls with HMI

- Supports Modbus, BACnet MS/TP or IP, and LonWorks

Electrical

- 208V / 230V / 460V, 3-phase

Certifications

- UL 60335-2-40 certified

- ETL listed for safe use with A2L refrigerants

Key Features

- Independent Temperature & Humidity Control: Allows separate management of sensible and latent loads for precise indoor climate control.

- High Efficiency: Achieves up to 50% reduction in electrical energy use compared to conventional systems.

- Low Dew Point Capability: Delivers supply air dew points as low as 35°F without the need for reheat or chilled water.

- Biocidal Properties: Liquid desiccant naturally disinfects air, enhancing indoor air quality.

- Low Maintenance: Desiccant lasts the life of the unit with minimal additional maintenance requirements.

- Flexible Installation: Drop-in replacement for packaged rooftop and DOAS applications, requiring only electrical connections.

Fisair Air Humidity Control Products

Koch Applied Solutions partners with Fisair to offer a variety of air humidity control technologies.

The Fisair lines include dehumidifiers for industrial materials and processes that require dry air, as well as low energy consumption evaporative coolers.

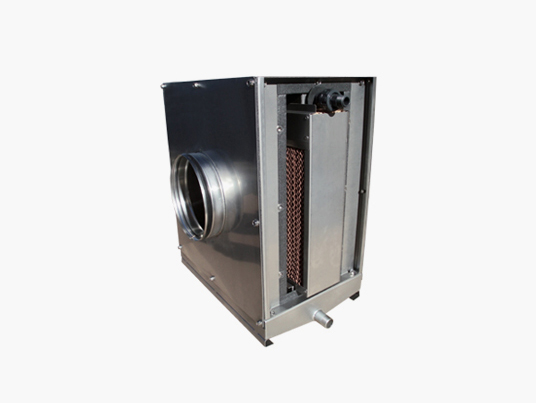

FDF Air Dehumidifiers

Many industrial materials and processes require dry air. Of the many processes available for drying air, desiccant rotor technology has proven to provide the best combination of low installation cost, flexibility, and efficient operating costs. Fisair supplies a range of desiccant dehumidifier series adapted to specific applications.

- A wide range of configurations

- Highly reliable equipment

- Drying capacities from 10 to 100 lbs/hr

- Dry air flow rates from 250 to 3500 CFM

- Flexible modular range

- Adaptable to specific solutions

- Highly reliable equipment

- Drying capacities from 100 to 350 lbs/hr

- Dry air flow rates from 4500 to 15,000 CFM

- Excellent low dew point performance

- Low energy consumption

- A wide range of configurations

- Highly reliable units

- Drying capacities from 10 to 100 lbs/hr

- Dry air flows from 250 to 3500 CFM

- Made from stainless steel

- Highly compact, robust and portable dehumidifiers

- High reliability and low energy consumption

- Mobile and heavy duty drying

- Series aimed at temporary drying

- Robust chassis and finish to protect against corrosion

- Ideal for surface treatment and rental applications

- Features additional fan to increase the drying capacity and wet air pressure

- Ice-free with no energy loss

- Units designed to reduce humidity in refrigerated areas and processes

- Thermal insulation, robust design and energy efficiency

HEF Evaporative Coolers

Dry air has a huge natural capacity for cooling by exchanging heat for water. These evaporative coolers are based on a low energy consumption operating principle.

- Adiabatic humidification and cooling systems

- AtomSpray water atomisation that uses compressed air as the fluid to drive water

- Most hygienic and efficient

- Contact panel evaporative humidifiers

- Best performance & efficiency at lower pressure drop and certified hygiene

- Low height solution

- Hygienic range for reduced heights

- Hygienic and efficient

- Contact panel evaporative humidifiers

- Low pressure drop efficiency and certified hygiene

- Contact panel evaporative humidifiers

Desiccant Rotors International (DRI) Desiccant Dehumidifiers

Koch Applied Solutions, a division of Koch Applied Solutions, LLC, is proud to partner with Desiccant Rotors International (DRI) for quality desiccant systems.

DRI is a global provider of products and systems for energy recovery, Indoor Air Quality, fresh air treatment, evaporative cooling, green buildings, dehumidification, and pollution control.

DRI desiccant cooling systems are open-cycle systems that use water as a refrigerant in direct contact with air. The cooling cycle combines evaporative cooling, air-to-air rotary heat exchangers, and desiccant dehumidification. Low-grade waste heat or solar heat from flat-plate solar thermal collectors are normally applied as a heating system for regeneration of the desiccant rotors.

- A flexible, modular, energy-efficient alternative

- Incorporating desiccant dehumidification plus evaporative cooling

- Regenerable using waste or solar heat, customizable to your building’s needs

Specially designed and configured for a particular station with a detailed study of the climate conditions (outdoor air data).

Specifications

Open-cycle water-based systems; integrate evaporative cooling, desiccant dehumidification, and heat exchange; regeneration via waste or solar heat; custom unit builds.

Features

- Special desiccant rotor chemistry

- Integrated evaporative and heat-exchange modules

- Custom casings, advanced sensors and controls

Applications

Ideal for environments requiring humidity and temperature control with energy-efficient dehumidification, particularly where waste/solar heat can regenerate desiccant; capable of climate-specific and solar-assisted system design.